- contact@phscameroun.com

- Iut ndogbong, douala - cameroun

🔥 Understanding the Classes of Fire

In engineering projects, fire safety is not just about installing alarms and extinguishers—it is about understanding the nature of fire itself. Fires are classified into categories based on the type of fuel involved. This classification is essential because each type of fire requires a specific suppression method. Using the wrong method can make the situation worse or even more dangerous.

The Five Main Classes of Fire

🔹 Class A – Solid Combustibles

-

Fuel: Wood, paper, textiles, plastics.

-

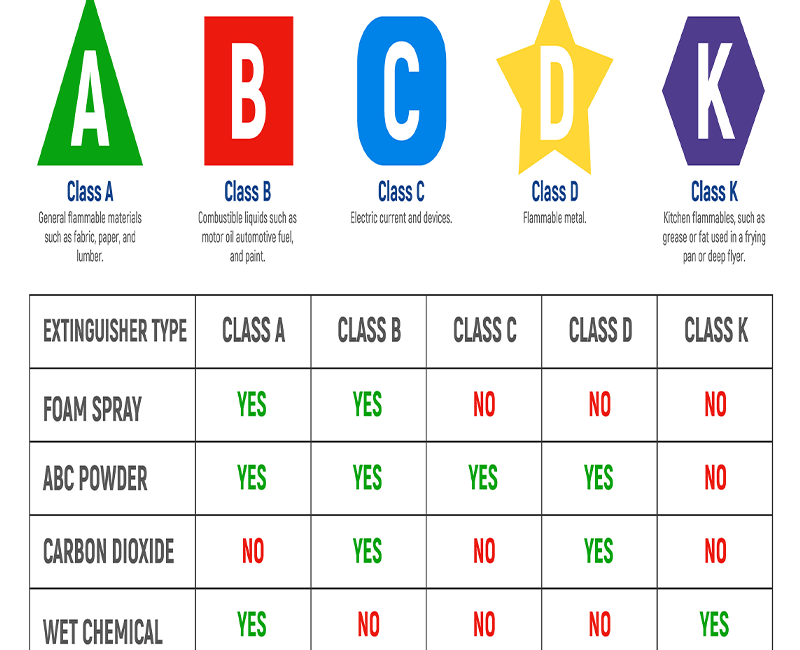

Extinguishing Method: Water or foam extinguishers, which cool and smother the fire.

-

Risk Example: Offices, warehouses, residential buildings.

🔹 Class B – Flammable Liquids

-

Fuel: Petrol, diesel, solvents, paints.

-

Extinguishing Method: Foam, dry chemical powder, or CO₂ to cut off oxygen supply.

-

Risk Example: Fuel stations, chemical plants, workshops.

🔹 Class C – Flammable Gases

-

Fuel: Propane, butane, methane, acetylene.

-

Extinguishing Method: Dry powder extinguishers, along with shutting off the gas supply.

-

Risk Example: Industrial facilities with gas pipelines or storage.

🔹 Class D – Combustible Metals

-

Fuel: Magnesium, sodium, potassium, titanium, lithium.

-

Extinguishing Method: Special dry powder designed for metal fires. Never use water, as it reacts violently with burning metals.

-

Risk Example: Metal processing industries, laboratories.

🔹 Class E (Electrical Fires) – Equipment under Voltage

-

Fuel: Electrical equipment, wiring, servers, machinery.

-

Extinguishing Method: CO₂ or dry powder. Water and foam must be avoided to prevent electrocution.

-

Risk Example: Data centers, factories, office equipment.

🔹 Class F (or K in some regions) – Cooking Oils & Fats

-

Fuel: Vegetable oils, animal fats at high temperature.

-

Extinguishing Method: Wet chemical extinguishers, which cool and create a barrier on the oil surface.

-

Risk Example: Industrial kitchens, restaurants, food processing plants.

Why Fire Classification Matters

-

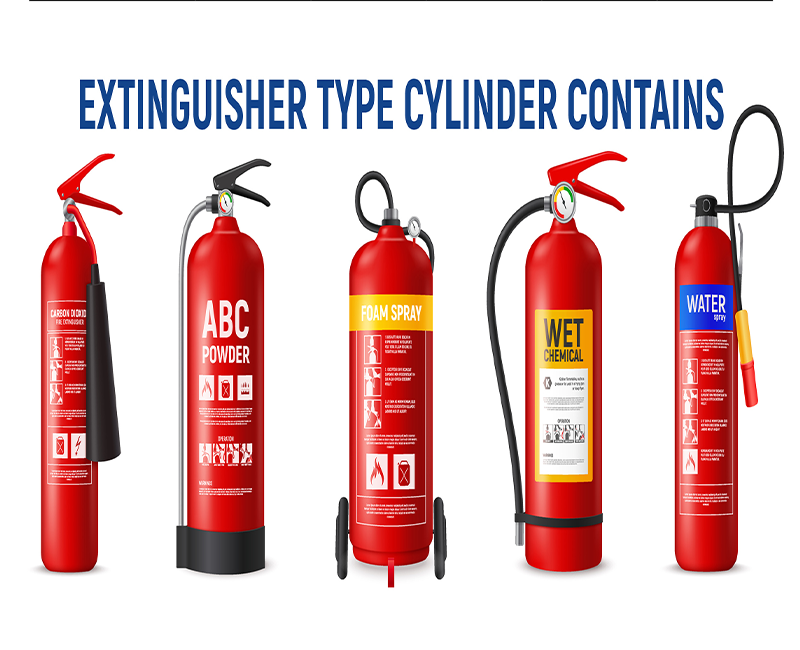

Correct Equipment Selection: Ensures the right extinguishers are installed for specific risks.

-

Enhanced Safety: Reduces the risk of using the wrong agent, which could spread the fire.

-

Regulatory Compliance: International standards (NFPA, ISO, EN) require proper fire risk assessment and equipment placement.

-

Training & Awareness: Employees trained on fire classes respond more effectively in emergencies.